Product ID: PM0005

| Width | 7m | 9m | 11m | 15m |

| 1-5m long | £12.45 | £14.75 | £17.00 | £20.35 |

| 6-24m long | £11.00 | £13.00 | £15.00 | £18.00 |

| 25m+ long | £10.50 | £12.50 | £14.50 | £17.50 |

Prices listed above are per metre. The more you buy, the more you save!

![]() Our most popular polythene cover incorporates an additive that increases its Thermic efficiency, yet still retains 90% light transmission. In simple terms the diffused polythene sheet helps trap and preserve higher temperatures inside the structures for much longer - in heated structures, a 15-20% fuel savings can be achieved. A beneficial side effect of this added additive is that light entering the polytunnel is diffused - scattering light evenly throughout the structure. This UV stabilised film is 200 microns (800 Gauge) and is supplied with a seven year guarantee.

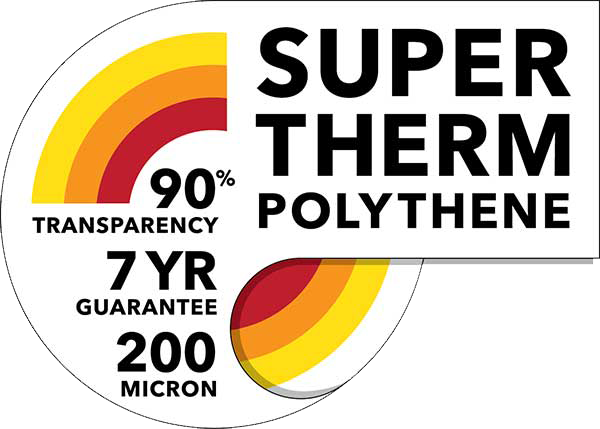

Our most popular polythene cover incorporates an additive that increases its Thermic efficiency, yet still retains 90% light transmission. In simple terms the diffused polythene sheet helps trap and preserve higher temperatures inside the structures for much longer - in heated structures, a 15-20% fuel savings can be achieved. A beneficial side effect of this added additive is that light entering the polytunnel is diffused - scattering light evenly throughout the structure. This UV stabilised film is 200 microns (800 Gauge) and is supplied with a seven year guarantee.

FOR USE WITH All crops where heat is important such as bedding/annual plants, propagation houses & over wintered vegetable production.

7m wide – 1.29kg per linear m - 50m roll would weigh 64.4kg

9m wide – 1.66kg per linear m - 50m roll would weigh 83kg

11m wide – 2.03kg per linear m - 50m roll would weigh 101.4kg

15m wide – 2.77kg per linear m - 50m roll would weigh 138.5kg

Please note - to help identify the polythene type and validate the guarantee, a series of numbers and letters are intermittently printed on the polythene sheet. The printing will appear approximately 1m from the side which will normally be buried into the ground or trimmed off.

Don't know how big a sheet you need? Use our Polytunnel Cover Calculator.

For discounted products please see our Clearance section, many sizes available.

Our polythene is exclusively sourced from Sotrafa in Spain, the world's biggest producer of horticultural film with an enviable reputation for quality thanks to exhaustive testing in the demanding weather conditions of Almeria.

First Tunnels are the sole distributor of Sotrafa products in the UK, and we are proud to work with the global leader to deliver the best possible products for our customers. UK suppliers make cheaper alternatives, but the quality simply doesn't compare.

Although guaranteed for 7 years against its biggest threat of sunlight degradation, when fitted correctly, it is not uncommon to hear our polythene covers have lasted in excess of 10 years.

View the terms of the Guarantee here.

Sunlight is the biggest enemy of polythene. While it's essential for the wellbeing of whatever you're growing, it also 'kills' polythene in much the same way you can find old discarded crisp packets lose their colour and become very brittle. First Tunnels polythene covers are developed and tested in the extreme conditions to give optimum performance and are UV stabilised to prevent the polythene from breaking down prematurely.

What is a KLy?

A Kilo-Langley is the measure of Solar energy radiated in 1 year. It varies from a minimum of 60 KLy in the Polar regions to 120 KLy in warm regions, and to a maximum of 200 KLy in the African desert. Southern Spain receives about 140 KLy whereas the UK receives about half of that, just 78KLy.

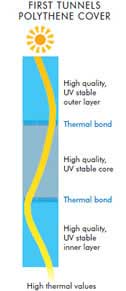

Our Super Therm polythene is 800 gauge/200 micron and made up of 3 layers for outstanding strength and performance.

We use a 3 layer polythene made of exceptional quality material, which has a hugely beneficial thermal effect.

The common misconception about polythene is the more layers, the better the product. Unfortunately this isn't true. More layers simply hide poor quality films, which are sandwiched inside a very average inner and outer skin. The result of these multi-layer (often called 5 or 6 layer) films is a noticeably poorer all-round performance - the thermal effect is significantly decreased.

Total Transmission of Visible Light

The amount of available light entering the polytunnel through the film. Measured as a percentage of total light.

Super Therm = 90%

Diffusion

The scattering of direct light entering the polytunnel ensuring no shadows, so all plants receive equal light. Measured as a percentage of total light.

Super Therm = 30%

Thermal Effect

A pocket of additives within the layers of the film that ensure and maintain a stable and optimum temperature within the polytunnel, especially during the night when it is colder.

Super Therm = 85%

Strength at Break

The load on a tested sample when it breaks. This is expressed in Pascals or MPa.

Super Therm = MD24/TD23

Elongation at Break

The strain on a tested sample when it stretches. This is also expressed in Pascals or MPa.

Super Therm = MD920/TD920

Creep

As the weather changes becoming hotter or colder, so the Polythene expands and contracts. Creep is the terms used to express this.

Super Therm = 5

Dart Test

A test to measure the impact strength on a test piece of plastic, using a weighted falling 'dart'.

Super Therm = 5

Please note - to help identify the polythene type and validate the guarantee, a series of numbers and letters are intermittently printed on the polythene. The printing will appear approximately 1m from the side which will normally be buried into the ground or trimmed off. Please retain a small piece containing the letters and numbers to validate the warranty. View the terms of the Guarantee here.

We strongly advise referring to the original Polytunnel Suppliers' construction guide when installing your polythene. The methods described herein may differ from those of the original manufacturer.

What is the Minimum Order Value?

We sell replacement polythene by the metre, 25m or 50m rolls in various widths with no waste and no cutting charge. Order values less than £50.00 will incur a £4.95 delivery charge. Please see the delivery tab for offshore delivery charges.

Does the Polythene come with a warranty?

Our Polythene is supplied with a guaranteed for 7 years against its biggest threat of sunlight degradation. When fitted correctly, it is not uncommon to hear our polythene covers have lasted in excess of 10 years.

Sunlight is the biggest enemy of polythene. While it's essential for the wellbeing of whatever you're growing, it also 'kills' polythene in much the same way you can find old discarded crisp packets lose their colour and become very brittle. First Tunnels polythene covers are developed and tested in the extreme conditions to give optimum performance and are UV stabilised to prevent the polythene from breaking down prematurely.

Please note - A series of numbers and letters are intermittently printed one metre from the edge, which should be either dug into a trench or trimmed off after installation. This printing is essential to help identify the polythene type and validate the guarantee.

Is there an inside or outside to my Polythene cover?

Each face of the Polythene sheet is identical, there is not a right or wrong side when choosing which face goes on the inside or outside of the Polytunnel structure. If condensation is a problem we have anti condensation spray available which is a non-toxic coating that reduces this effect.

Where is the Polythene Sourced from?

Our polythene is exclusively sourced from Sotrafa in Spain, the world's biggest producer of horticultural film with an enviable reputation for quality thanks to exhaustive testing in the demanding weather conditions of Almeria.

First Tunnels are the sole distributor of Sotrafa products in the UK, and we are proud to work with the global leader to deliver the best possible products for our customers. UK suppliers make cheaper alternatives, but the quality simply doesn't compare.

What is the Thickness of the Polythene?

Our polythene is 800 gauge/200 micron and made up of 3 layers for outstanding strength and performance. We use a 3 layer polythene made of exceptional quality material, which has a hugely beneficial thermal effect.

The common misconception about polythene is the more layers, the better the product. Unfortunately this isn't true. More layers simply hide poor quality films, which are sandwiched inside a very average inner and outer skin. The result of these multi-layer (often called 5 or 6 layer) films is a noticeably poorer all-round performance - the thermal effect is significantly decreased.

Do you provide further data regarding the Polythene specification?

Data for Optical and Mechanical properties can be viewed here.

All polytunnel accessories will be despatched within 1-3 working days. Should you have any query regarding a delivery, please contact us on 01282 601253.

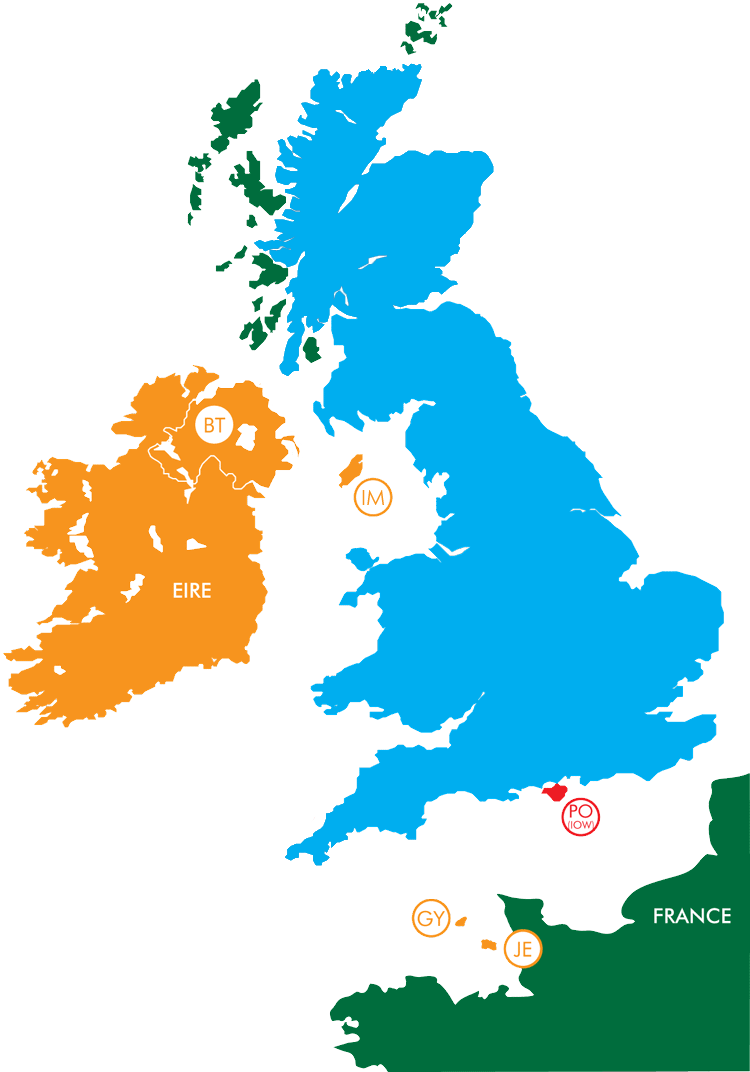

Customers in the Blue and Red areas with an order value less then £75.00, shipping costs will be £4.95. For orders above £75.00, delivery is FREE. For customers in the Orange areas, shipping costs will be £80 for Eire and £30 for Northern Ireland irrespective of order value. Please note, the cost of £80 for customers in Eire includes a £50 customs clearance charge which we pay in advance on your behalf, ensuring there are no unexpected costs upon import.

For those very small orders, such as tape, books or irrigation spares, we may be able to offer a smaller charge to cover postage and packing, please call the office for a quote.

For all other areas within Europe, please proceed to the checkout for a shipping quote. Should your country not be listed, please contact us for a shipping quote.

If you have any concerns regarding delivery please telephone our office on 01282 601253.

Note: If you purchase a Commercial and Domestic Polytunnel, then Shipping Charges for the Polytunnel are applicable.